Purpose:

Accurately and rapidly measure the concentration of NOx in gas and transmit the signal to ECU.

Working Principle:

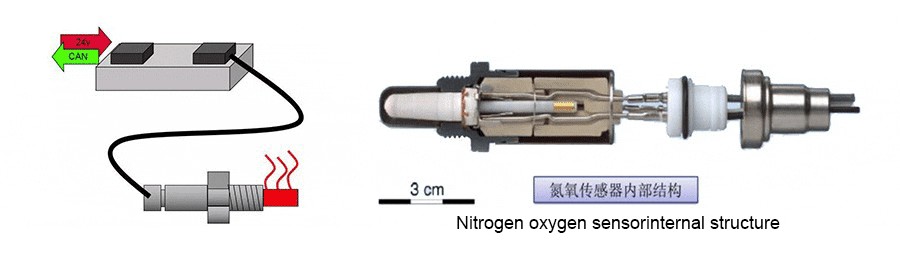

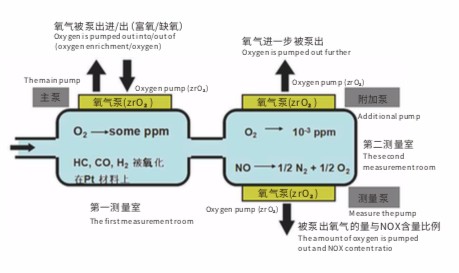

The core component of nitrogen and oxygen sensor is porous ZRO2, zirconia ceramic tube. It is a solid electrolyte. Porous platinum (PT) electrodes are sintered on both sides. When heated to a certain temperature, due to the different oxygen concentration on both sides, zirconia will react chemically. The charge on both sides of the electrodes will move. The concentration of nitrogen and oxygen will be different according to the current generated. The concentration of nitrogen and oxygen is fed back to ECU and processed accordingly.

In the first measurement chamber, the oxygen in the exhaust gas is pumped out while HC, CO and H2 are oxidized on the platinum material.

In the second measuring chamber, NO_x is reduced on the catalytic material and O_2 is released at the same time.

Measuring the amount of oxygen produced in the second chamber represents the content of NOx.

Features: High sensitivity, fast data stability and response speed, reliable quality without delay and good stability; wide application range (characteristic) dew point protection function: because the nitrogen and oxygen sensor itself needs higher temperature when the electrode works, and the nitrogen and oxygen sensor has ceramic structure inside. Ceramics can touch water at high temperature. After meeting water, it is easy to expand and shrink, which will lead to ceramic cracking. Therefore, the nitrogen and oxygen sensor will set a dew point protection function. The function of this function is to wait for a period of time after the temperature of the exhaust pipe reaches the set value. ECU or DCU believe that even water on nitrogen and oxygen sensors can be blown dry by high-temperature exhaust gas at such high temperatures.

When the ignition switch is turned on, the nitrogen and oxygen sensor (NOx) will be heated to 100 C, and then wait for the "dew point" temperature signal from the ECU or DCU. When the nitrogen and oxygen sensor receives the instruction from the ECU or DCU, the sensor will heat itself to a fixed temperature (up to 800 C).